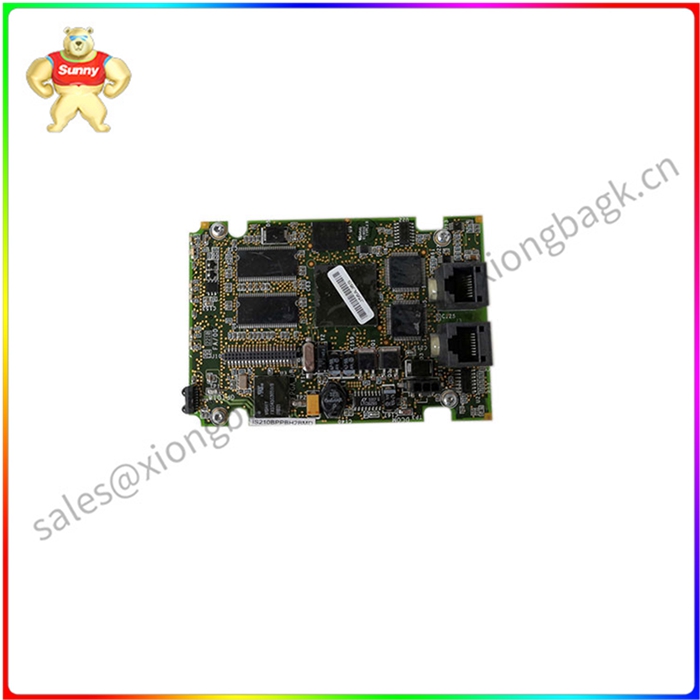

IS210BPPBH2BMD Mark VI印刷电路板 分散控制系统

IS210BPPBH2BMD Mark VI印刷电路板是Mark VI分布式控制系统(DCS)的关键组成部分,一个广泛使用的工业应用自动化平台。它在传输和处理控制信号方面起着至关重要的作用,能够精 确可靠地控制各种工业过程。

IS210BPPBH2BMD Mark VI 印刷电路板的主要特点:

信号传输:促进各种控制系统组件之间的模拟和数字信号传输,确保DCS网络内的无缝通信。

信号处理:执行信号处理任务,如放大,滤波和转换,准备信号以进行适当的控制和监测。

数据采集:从传感器和现场设备获取数据,提供有关所控制过程的实时信息。

控制执行:执行从DCS控制器接收的控制算法和命令,将它们转化为操作流程变量的操作。

故障检测和诊断:监控系统运行状况并检测潜在故障,从而及时进行故障排除和预防性维护。

使用 IS210BPPBH2BMD Mark VI 印刷电路板的好处:

增强的过程控制:实现对工业过程的精 确和可靠控制,从而提高产品质量并降低生产成本。

提高系统可靠性:通过提供强大的信号传输,zui大限度地减少停机时间并确保连续运行,加工和故障检测功能。

可扩展和灵活的控制:支持广泛的控制应用,并轻松适应不断变化的过程要求。

简化系统维护:由于其模块化设计和标准化组件,便于故障排除和维护。

延长系统寿命:通过提供可靠的性能和减少频繁更换的需要,延长系统寿命。

实施 IS210BPPBH2BMD Mark VI 印刷电路板的注意事项:

系统兼容性:验证模块是否符合特定的Mark VI DCS配置和硬件要求。

安装和配置:遵循正确的安装和配置程序,以确保准确的信号传输,加工并控制执行。

维护和支持:实施定期维护程序并遵守制造商的支持指南,以保持zui佳模块性能并解决任何潜在问题。

系统升级:使DCS软件和固件保持zui新状态,以确保与zui新模块的兼容性,并从性能增强中受益。

IS210BPPBH2BMD Mark VI印刷电路板 分散控制系统

The IS210BPPBH2BMD Mark VI printed circuit board is a key component of the Mark VI Distributed Control System (DCS), a widely used automation platform for industrial applications. It plays a vital role in transmitting and processing control signals, enabling accurate and reliable control of various industrial processes.

IS210BPPBH2BMD Mark VI Printed circuit board features:

Signal transmission: Facilitates the transmission of analog and digital signals between various control system components, ensuring seamless communication within the DCS network.

Signal processing: Performs signal processing tasks such as amplification, filtering, and conversion, preparing signals for appropriate control and monitoring.

Data acquisition: Obtain data from sensors and field devices to provide real-time information about the process under control.

Control execution: The execution of control algorithms and commands received from the DCS controller, converting them into operations that manipulate process variables.

Fault detection and diagnosis: Monitor system health and detect potential faults for timely troubleshooting and preventive maintenance.

Benefits of using IS210BPPBH2BMD Mark VI Printed circuit Boards:

Enhanced process control: Achieve precise and reliable control of industrial processes to improve product quality and reduce production costs.

Improve system reliability: By providing robust signal transmission, minimize downtime and ensure continuous operation, processing and fault detection capabilities.

Scalable and flexible control: Supports a wide range of control applications and easily ADAPTS to changing process requirements.

Simplified system maintenance: Easy troubleshooting and maintenance thanks to its modular design and standardized components.

Extend system life: Extend system life by providing reliable performance and reducing the need for frequent replacement.

Precautions for implementing IS210BPPBH2BMD Mark VI printed circuit board:

System compatibility: Verify that the module meets specific Mark VI DCS configuration and hardware requirements.

Installation and configuration: Follow proper installation and configuration procedures to ensure accurate signal transmission, machining and control execution.

Maintenance and support: Implement regular maintenance procedures and follow the manufacturer's support guidelines to maintain optimal module performance and address any potential issues.

System upgrades: Keep DCS software and firmware up to date to ensure compatibility with the latest modules and benefit from performance enhancements.

QQ在线客服

QQ在线客服