IS210AEBIH3BEC 小型辅助板 专为蒸汽或燃气轮机管理而设计

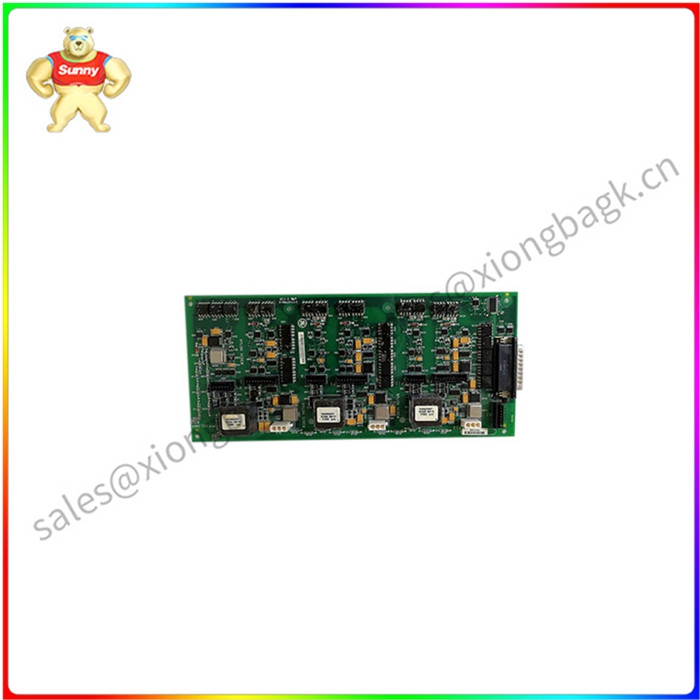

IS210AEBIH3BEC小型辅助板是一种多功能且可靠的模块,专为蒸汽或燃气轮机管理应用而设计。它为监测和控制各种涡轮机参数提供了紧凑而高效的解决方案,确保发电厂安全高效运行。

IS210AEBIH3BEC小型辅助板的主要特点:

涡轮机参数监控:监控关键的涡轮机参数,如速度、压力、温度、和振动,提供对涡轮机性能和状况的实时洞察。

控制和监管:实施控制和调节算法以保持zui佳的涡轮机运行条件,确保高效发电并zui大限度地减少排放。

数据记录和分析:随时间推移记录和分析涡轮机数据,实现趋势分析,故障检测,和预测性维护。

沟通与整合:支持各种通信协议和接口,可与监控和数据采集 (SCADA) 系统以及涡轮机控制系统集成。

紧凑型设计:采用紧凑型设计,便于集成到涡轮机控制柜中。

使用IS210AEBIH3BEC小型辅助板的好处:

增强的涡轮机性能:通过提供实时监控来优化涡轮机性能, control,和监管能力。

提高可靠性和安全性:通过检测潜在故障和实施保护措施,提高涡轮机的可靠性和安全性。

降低维护成本:通过及早发现潜在问题来促进预测性维护,zui大限度地减少计划外停机时间和维护成本。

延长涡轮机寿命:通过确保zui佳运行条件和防止过早磨损来延长涡轮机的使用寿命。

数据驱动的决策:为有关涡轮机运行的明智决策提供有价值的数据见解,保养和优化策略。

实施IS210AEBIH3BEC小型辅助板的注意事项:

涡轮机兼容性:验证模块与特定涡轮机型号和控制系统的兼容性。

安装和配置:遵循正确的安装和配置过程,以确保准确可靠的数据收集和控制功能。

数据管理:建立数据存储程序,分析并报告以有效利用收集到的涡轮机数据。

维护和支持:遵循定期维护程序并遵守制造商的支持指南,以确保zui佳的模块性能并解决任何潜在问题。

IS210AEBIH3BEC 小型辅助板 专为蒸汽或燃气轮机管理而设计

The IS210AEBIH3BEC Small auxiliary board is a versatile and reliable module designed for steam or gas turbine management applications. It provides a compact and efficient solution for monitoring and controlling various turbine parameters, ensuring safe and efficient operation of power plants.

IS210AEBIH3BEC small auxiliary board main features:

Turbine Parameter Monitoring: Monitors key turbine parameters such as speed, pressure, temperature, and vibration to provide real-time insight into turbine performance and condition.

Control and regulation: Implement control and regulation algorithms to maintain optimal turbine operating conditions, ensure efficient power generation and minimize emissions.

Data logging and analysis: Record and analyze turbine data over time for trend analysis, fault detection, and predictive maintenance.

Communication and integration: Supports a variety of communication protocols and interfaces for integration with supervisory control and Data acquisition (SCADA) systems and turbine control systems.

Compact design: Compact design for easy integration into the turbine control cabinet.

Benefits of using IS210AEBIH3BEC small auxiliary board:

Enhanced Turbine Performance: Optimize turbine performance, control, and regulatory capabilities by providing real-time monitoring.

Improve reliability and safety: Improve turbine reliability and safety by detecting potential failures and implementing protective measures.

Reduce maintenance costs: Promote predictive maintenance by identifying potential problems early, minimizing unplanned downtime and maintenance costs.

Extend turbine life: Extend the service life of turbines by ensuring optimal operating conditions and preventing premature wear.

Data-driven decision-making: Provides valuable data insights for informed decisions about turbine operation, maintenance and optimization strategies.

Precautions for implementing IS210AEBIH3BEC small auxiliary board:

Turbine compatibility: Verify module compatibility with specific turbine models and control systems.

Installation and configuration: Follow proper installation and configuration procedures to ensure accurate and reliable data collection and control functions.

Data management: Establish data storage procedures, analyze and report to make effective use of collected turbine data.

Maintenance and support: Follow regular maintenance procedures and follow the manufacturer's support guidelines to ensure optimal module performance and resolve any potential issues.

QQ在线客服

QQ在线客服