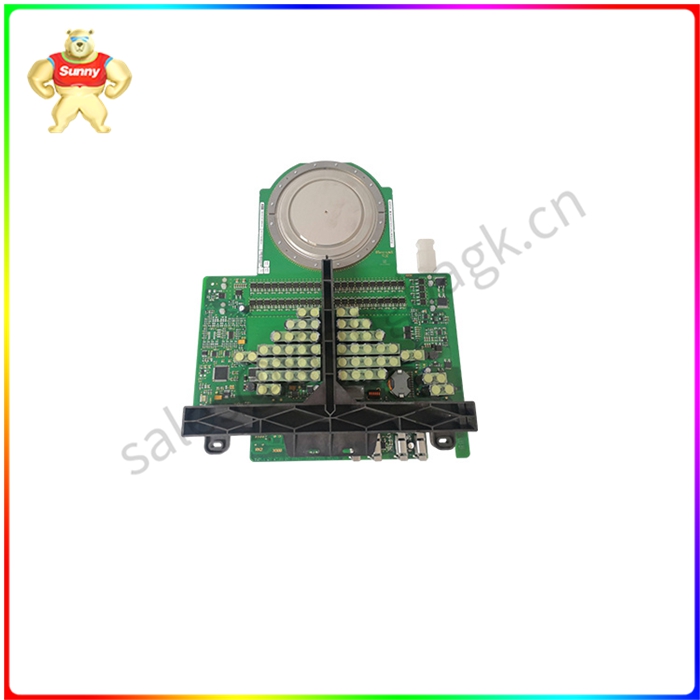

5SHY3545L0016 3BHB020720R0002 半导体模块

集成栅极换流晶闸管IGCT(Intergrated Gate Commutated Thyristors)是1996年问世的用于巨型电力电子成套装置中的新型电力半导体器件。IGCT是一种基于GTO结构、利用集成栅极结构进行栅极硬驱动、采用缓冲层结构及阳极透明发射极技术的新型大功率半导体开关器件,具有晶闸管的通态特性及晶体管的开关特性。由于采用了缓冲结构以及浅层发射极技术,因而使动态损耗降低了约50%,另外,此类器件还在一个芯片上集成了具有良好动态特性的续流二极管,从而以其独特的方式实现了晶闸管的低通态压降、高阻断电压和晶体管稳定的开关特性有机结合.

IGCT使变流装置在功率、可靠性、开关速度、效率、成本、重量和体积等方面都取得了巨大进展,给电力电子成套装置带来了新的飞跃。IGCT是将GTO芯片与反并联二极管和栅极驱动电路集成在一起,再与其栅极驱动器在外围以低电感方式连接,结合了晶体管的稳定关断能力和晶闸管低通态损耗的优点,在导通阶段发挥晶闸管的性能,关断阶段呈现晶体管的特性。IGCT具有电流大、电压高、开关频率高、可靠性高、结构紧凑、损耗低等特点,而且造成本低,成品率高,有很好的应用前景。采用晶闸管技术的GTO是常用的大功率开关器件,它相对于采用晶体管技术的IGBT在截止电压上有更高的性能,但广泛应用的标准GTO驱动技术造成不均匀的开通和关断过程,需要高成本的dv/dt和di/dt吸收电路和较大功率的栅极驱动单元,因而造成可靠性下降,价格较高,也不利于串联。但是,在大功率MCT技术尚未成熟以前,IGCT已经成为高压大功率低频交流器的优选方案。

IGCT与GTO相似,也是四层三端器件,GCT内部由成千个GCT组成,阳极和门极共用,而阴极并联在一起。与GTO有重要差别的是IGCT阳极内侧多了缓冲层,以透明(可穿透)阳极代替GTO的短路阳极。导通机理与GTO完全一样,但关断机理与GTO完全不同,在IGCT的关断过程中,GCT能瞬间从导通转到阻断状态,变成一个pnp晶体管以后再关断,所以它无外加du/dt限制;而GTO必须经过一个既非导通又非关断的中间不稳定状态进行转换(即”GTO区”),所以GTO需要很大的吸收电路来抑制重加电压的变化率du/dt。阻断状态下IGCT的等效电路可认为是一个基极开路、低增益pnp晶体管与栅极电源的串联。

IGCT触发功率小,可以把触发及状态监视电路和IGCT管芯做成一个整体,通过两根光纤输入触发信号、输出工作状态信号。IGCT将 GTO技术与现代功率晶体管IGBT的优点集于一身,利用大功率关断器件可简单可靠地串联这一关键技术,使得IGCT在中高压领域以及功率在 0.5MVA~100MVA的大功率应用领域尚无真正的对手。

IGCT损耗低、开关快速等这些优点保证了它能可靠、高效率地用于300 kVA~10MVA变流器,而不需要串联或并联。在串联时,逆变器功率可扩展到100MVA。虽然高功率的IGBT模块具有一些优良的特性,如能实现di/dt和dv/dt 的有源控制、有源箝位、易于实现短路电流保护和有源保护等。但因存在着导通高损耗、损坏后造成开路以及无长期可靠运行数据等缺点,限制了高功率IGBT模块在高功率低频变流器中的实际应用。因此IGCT将成为高功率高电压变频器的首 选功率器件。

5SHY3545L0016 3BHB020720R0002 半导体模块

Intergrated Gate Commutated Thyristors (IGCT) is a new type of power semiconductor device used in large power electronics set, which was developed in 1996. IGCT is a new type of high-power semiconductor switching device based on GTO structure, using integrated gate structure to drive the gate hard, using buffer layer structure and transparent anode emitter technology, which has the on-state characteristics of thyristor and the switching characteristics of transistor. Due to the use of buffer structure and shallow emitter technology, the dynamic loss is reduced by about 50%, in addition, such devices are also integrated on a chip with good dynamic characteristics of the continuous current diode, so that in its unique way to achieve the low on-state voltage drop, high blocking voltage and transistor stable switching characteristics of the organic combination.

IGCT has made great progress in power, reliability, switching speed, efficiency, cost, weight and volume, and has brought a new leap to power electronic complete sets. IGCT integrates the GTO chip with the anti-parallel diode and the gate driver circuit, and then connects it with the gate driver in a low inductance mode at the periphery, combining the stable turn-off ability of the transistor and the advantages of the low on-state loss of the thyristor, giving play to the performance of the thyristor in the on-stage, and presenting the characteristics of the transistor in the off stage. IGCT has the characteristics of high current, high voltage, high switching frequency, high reliability, compact structure, low loss, low cost, high yield, and has a good application prospect. GTO using thyristor technology is a commonly used high-power switching device, which has higher performance in cut-off voltage than IGBT using transistor technology, but the widely used standard GTO drive technology causes uneven on-off and off-off processes, requiring high cost dv/dt and di/dt absorption circuits and high-power gate drive units. As a result, reliability is reduced, the price is higher, and it is not conducive to series. However, before the high-power MCT technology is not mature, IGCT has become the preferred solution for high-voltage high-power low-frequency communicators.

An IGCT is similar to a GTO in that it is also a four-layer, three-terminal device, consisting of thousands of GCTTS inside the GCT, with the anode and gate shared and the cathode in parallel. The important difference with GTO is that the IGCT anode has a buffer layer inside, and the transparent (penetrable) anode replaces the short-circuit anode of GTO. The turn-on mechanism is exactly the same as that of GTO, but the turn-off mechanism is completely different from that of GTO. In the turn-off process of IGCT, GCT can instantly change from the turn-on state to the blocking state, and become a pnp transistor and then turn off, so it has no additional du/dt limitation; The GTO must pass through an intermediate unstable state that is neither on nor off (the "GTO zone"), so the GTO needs a large absorption circuit to suppress the change rate du/dt of the reapplied voltage. The equivalent circuit of IGCT in the blocked state can be considered as a series of an open base, low gain pnp transistor and a gate power supply.

The IGCT trigger power is small, and the trigger and condition monitoring circuit and IGCT tube core can be made into a whole, and the trigger signal is input and the working state signal is output through two optical fibers. IGCT combines the advantages of GTO technology and modern power transistor IGBT in one, using the key technology of simple and reliable series series of high-power turn-off devices, making IGCT in the field of high-voltage and high-power applications with power between 0.5MVA and 100MVA without real rivals.

The advantages of low loss and fast switching of IGCT ensure that it can be used reliably and efficiently in 300kVA ~ 10MVA converters without series or parallel connection. In series, the inverter power can be extended to 100MVA. Although the high power IGBT module has some excellent characteristics, such as active control of di/dt and dv/dt, active clamping, easy to achieve short circuit current protection and active protection. However, due to the defects of high conduction loss, open circuit caused by damage and no long-term reliable operation data, the practical application of high power IGBT module in high power low frequency converter is limited. Therefore, IGCT will become the preferred power device for high power and high voltage inverter.

5SHY3545L0016 3BHB020720R0002 半导体模块

| ABB | PFSA140 |

| GE | IS200ACLEH1BCB |

| GE | IS215ACLEH1B |

| ABB | PM891K01 |

| ABB | PM865K02 |

| FOXBORO | H927069B0700 |

| ABB | EL3020 二氧化硫、氮氧化物、O2 |

| ABB | PM665 3BDS005799R1 |

| ABB | PFSK151 |

| ABB | PM866AK02 |

QQ在线客服

QQ在线客服