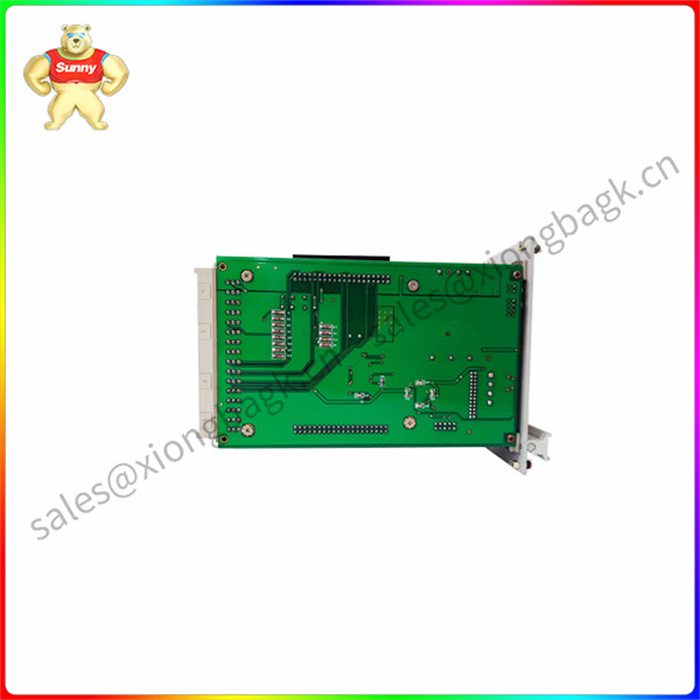

MMS6823 旋转机械振动监测数据采集和通讯模件

产品描述

MMS6823 EPRO旋转机械振动监测数据采集和通讯模件用于收集和通信旋转机械的振动监测数据。

特征

8路RS 485输入

数据输出方式:

-MODBUS RTU/ASCII

-以太网TCP/IP

两种总线输出方式并行,相互间不影响。

MODBUS总线的输出方式

RTU/ASCII可任选。可传输特征值,模件实时波形数据,以及模件状态和报警状态等物理量。

键相信号调整功能

冗余电源输入

采用标准的19”框架模件

MMS6823 EPRO模块是一种高性能设备,用于收集和传输旋转机械的振动数据。它提供了对振动信号的精 确测量和分析,能够及早发现潜在问题并制定有效的维护计划。

MMS6823通过RS485总线不断地访问连接在总线上的MMS6000模件来实现数据实时采集功能,同时将接收到特征值数据和报警及模件状态数据转换成标准MODBUS协议和TCP/IP协议输出。

MMS6823通过RS-485通讯口与MMS6000汽轮机监测保护系统的RS485总线连接,获取MMS6000系统各测量模件的实时数据。由于数据直接取自测量模块,无需中间处理,因而具有其它采样方式无可比拟的精度。系统采用同步整

周期方式采集数据,采样点数可选,zui大采样点数为1024。可采集起/停机(瞬态)和稳态的振动数据及相关过程参数。系统从瓦振和轴振得到动态信号,从轴位移、偏心和差胀测量模件等得到静态信号。从转速模件获得设备的转速和键相信号。

数据采集,通讯服务程序采用多线程技术,各MMS6000模件通道的数据读写操作全部并行化,每一个串口都由一个单独的线程来完成读写工作,保证通道之间的数据是同步的。

MMS6823 旋转机械振动监测数据采集和通讯模件

Product description

MMS6823 EPRO Vibration Monitoring Data acquisition and communication module is used to collect and communicate vibration monitoring data of rotating machinery.

trait

Eight RS 485 inputs

Data output mode:

-MODBUS RTU/ASCII

- Ethernet TCP/IP

The two bus output modes are parallel and do not affect each other.

MODBUS Indicates the output mode of the bus

RTU/ASCII Optional. It can transmit characteristic values, real-time waveform data of modules, and physical quantities such as module status and alarm status.

Key key adjustment function

Redundant power input

Standard 19 "frame modules are used

The MMS6823 EPRO module is a high-performance device for collecting and transmitting vibration data of rotating machinery. It provides accurate measurement and analysis of vibration signals, enabling early detection of potential problems and effective maintenance planning.

The MMS6823 continuously accesses the MMS6000 module connected to the bus through the RS485 bus to realize the real-time data acquisition function, and converts the received feature value data, alarm and module status data into standard MODBUS and TCP/IP protocol output.

MMS6823 is connected to RS485 bus of MMS6000 steam turbine monitoring and protection system through RS-485 communication port to obtain real-time data of each measurement module of MMS6000 system. Because the data is taken directly from the measurement module, there is no intermediate processing, so it has an unparalleled accuracy of other sampling methods. The system adopts synchronous integration

Data is collected periodically. The sampling number is optional. The maximum sampling number is 1024. Vibration data and related process parameters for start/stop (transient) and steady state can be collected. The system obtains dynamic signals from tile vibration and shaft vibration, and static signals from axial displacement, eccentricity and differential expansion measurement modules. Get the device's speed and key trust number from the speed module.

Data acquisition, communication service program using multi-thread technology, each MMS6000 module channel data read and write operations are all parallel, each serial port by a separate thread to complete the read and write work, to ensure that the data between the channels is synchronized.

MMS6823 旋转机械振动监测数据采集和通讯模件

| ABB | CP651 |

| ABB | REM615 |

| ABB | SPAD346C1-AA |

| EPRO | A6310 |

| ABB | CI867K01 |

| VMIC | VMIPCI-5565-110000 |

| KONGSBER | RDIOR400 |

QQ在线客服

QQ在线客服